Application scenarios

Contact us

Add:6th Floor, Building 1, Huaqing Creative Park, No. 33 Zhihui Road, Huishan Economic Development Zone, Wuxi City

Tel:+86-510-88818999

Fax:+86-510-85108252

E-mail:jsfg@fg-furnace.com

Ceramic liner rotary kiln

Fenggu ceramic liner rotary kiln, also known as composite ceramic rotary kiln, is capable of automatic feeding and discharging, realizing continuous production and increasing production efficiency by more than 30%. The equipment automatic temperature control, atmosphere control with high precision, the use of dynamic tumbling heating, more uniform heating, and sintering is completed, the metal magnetic foreign matter indicators are extremely low, suitable for new energy lithium materials, nano-materials sintering.

Category:

keyword:Experimental rotary kiln

Description

PRODUCT FEATURES

1. Ceramic liner technology, eliminating metal precipitation

Adopt ceramic inner liner, no metal contact in the sintering process, achieve full metal isolation from the source, ensure the purity of the powder, and completely solve the industry pain point of metal pollution in the sintering process.

2. Dynamic tumbling heating, fast and uniform

Replace the traditional static sagger sintering method, so that the material dynamic tumbling heating, to overcome the static sintering of the material produced by over-burning, entrapment and other defects, greatly improving the uniformity and stability of the material heat.

3. production efficiency by more than 30%, energy consumption by more than 50%

Automatic feeding and discharging, continuous production, compared with the traditional sintering furnace, production efficiency is greatly improved, operating costs are greatly reduced, very cost-effective.

4. Dynamic sealing system, no leakage

Special dynamic sealing structure, effectively protect the rotary kiln airtight, no leakage, thus ensuring the purity of the material, improve the quality of the user's products.

5. Partition temperature control, high precision atmosphere control

Automatic partition temperature control, can realize the temperature zone not less than 5, supplemented by PLC control, man-machine interaction, save time and effort, data at a glance.

Performance Parameters

| Furnace type: continuous non-metallic rotary kiln | Output: 100kg/h~1000 kg/h |

| Maximum working temperature: 1000 ℃ | Heating power: 552 kw |

| Processing atmosphere: oxygen, compressed air or atmosphere | Heating method: zoned electric heating |

| Processing materials: powder, block, powder material | Speed: 0.3~3 r/min |

| Inner tank diameter: φ800 mm | Gas flow range: 0~200 (m³/h) |

| Inner tank length: 16000 mm | Oxygen and compressed air pressure: 0~0.4 Mpa |

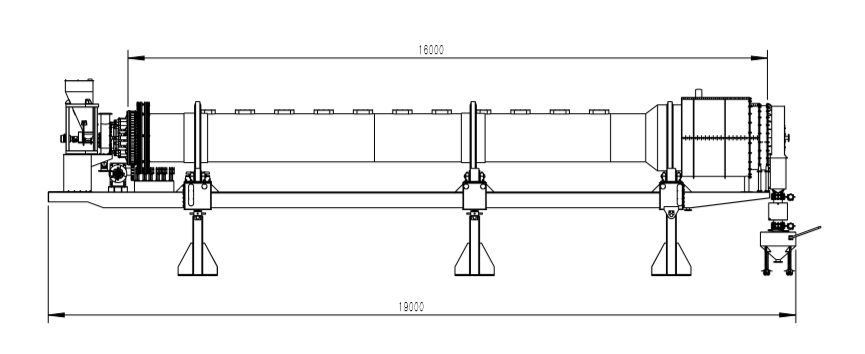

Overall Dimension

Related products

Message