Product Center

Professional kiln thermal equipment manufacturers

Continuous atmosphere rotary kiln

High temperature resistance, corrosion resistance. Atmosphere control, continuous use. Suitable for high-end powder materials such as lithium battery positive and negative electrodes.

Heating and cooling in one ceramic liner rotary kiln

Using composite ceramic inner tank to ensure the purity of the powder. After sintering, the increment of metal magnetic foreign objects is ≤ 20 PPB. It is heated in the form of dynamic tumbling, without overburning and entrainment. Fully sealed structure ensures no leakage point in sintering process. Partition temperature control, temperature control zone is not less than 5. Continuous production, high productivity.

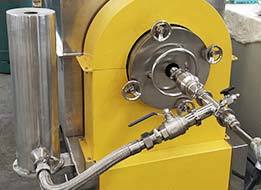

Discontinuous atmosphere rotary kiln

Replaceable liner, suitable for testing. Dynamic sintering, energy-saving and high efficiency. Applicable to new energy materials.

Quartz sand purification rotary kiln

Applicable to the purification process of quartz sand calcined at high temperature. 950℃ high temperature out of the kiln. Large output continuous production. High precision of temperature control.

High temperature and pressure resistance, good airtightness. High temperature control accuracy. Applicable to new materials and new processes.

Heating and cooling split up and down ceramic liner rotary kiln

Using composite ceramic inner tank to ensure the purity of the powde. After sintering, the increment of metal magnetic foreign objects is ≤ 20 PPB. It is heated in the form of dynamic tumbling, without overburning and entrainment. Fully sealed structure ensures no leakage point in sintering process. Partition temperature control, temperature control zone is not less than 5. Continuous production, high productivity.

Heating and cooling split up and down ceramic liner rotary kiln

Using composite ceramic inner tank to ensure the purity of the powder. After sintering, the increment of metal magnetic foreign objects is ≤ 20 PPB. It is heated in the form of dynamic tumbling, without overburning and entrainment. Fully sealed structure ensures no leakage point in sintering process. Zone temperature control, with 5-10 controllable temperature zones. Continuous production, high productivity.

Lithium battery recovery rotary kiln

Continuous rotary kiln, large output. Specially made metal liner, corrosion and wear resistance. Atmosphere control, dynamic tumbling sintering.

Continuous atmosphere rotary kiln

High temperature resistance, corrosion resistance. Atmosphere control, continuous use. Suitable for high-end powder materials such as lithium battery positive and negative electrodes.

Four Major Advantages

Fenggu Intermittent Atmosphere Rotary Kiln, Your wiser Choice

★ Detachable and replaceable inner liner with different materials...

★ Production efficiency has increased by more ....

★ Dynamic heating, fast and uniform

★ Automatic temperature control, convenient operation

★ Suitable for various calcination materials

Suitable for battery materials, rare earth materials, magnetic...

Four Major Advantages

Fenggu Intermittent Atmosphere Rotary Kiln, Your wiser Choice

Application Scenarios

Professional kiln thermal equipment manufacturers

Fenggu focuses on developing a new type of powder sintering rotary kiln

Undertake the design of global powder sintering rotary kilns and provide customized sintering furnace research and manufacturing for powder experiments, production, etc

Service Process

Professional kiln thermal equipment manufacturers

Requirement submission

Material testing

Equipment Selection

Customized production

Freight distribution

On site debugging

Operation and maintenance

Three Reasons to Choose Fenggu

Professional kiln thermal equipment manufacturers

More reliable brands

Focusing on the development of sintering equipment, serving the top ten lithium battery enterprises with multiple certificates

◆ Accumulated in the industry in the past 10 years, a trustworthy brand, focusing on the development of material sintering equipment

◆ Long term strategic cooperation with Fortune 500 companies and multiple research institutions, deeply trusted by customers

◆ Dozens of national certificates certified as brand endorsements, possessing independent intellectual property rights, professional and focused

A more professional team

Supported by research institutions, senior R&D engineers, and nationwide rapid response

◆ Collaborating with numerous research institutions, updating concepts and technologies, and improving product performance

◆ Senior technical personnel in the field of sintering equipment, providing customized product development for customers

◆ Serving nationwide, actively and quickly responding, providing customers with more reliable services

More comprehensive services

Exclusive sintering customized design, 7 * 24 technical support, lifelong after-sales operation and maintenance

◆ A one-on-one technical research team that deeply understands customer needs and provides customized solutions

◆ 24-hour online technical support, providing fast technical emergency support, and helping customers solve problems

◆ To provide lifelong product operation and maintenance services for cooperative customers, conduct regular follow-up visits, and promptly solve problems

Company Profile

Professional kiln thermal equipment manufacturers

Jiangsu Fenggu Energy-Saving Technology Co., Ltd. is the holding subsidiary of Rongbai Technology, a leading lithium battery cathode material enterprise. It has been focusing on the integrated services of technology research and development, manufacturing, installation and commissioning and technical consulting of various kiln thermal heating equipment.

Thanks to the users who allow us to display their talents, the design schools that support us, the partners who work together with us, and the competitors who promote our continuous progress. We will not forget the original intention, forge ahead, with excellent quality, excellent service, dedicated to domestic and foreign customers.

Corporate Style

Professional kiln thermal equipment manufacturers

Factory floor

Factory floor

Office

Office

Factory floor

Cooperation Partner

Professional kiln thermal equipment manufacturers

News Center

Always adhere to the principle of seeking development and survival through quality

Take you to understand the new trends in the industry

05

/

20

Company news

Fenggu Energy Saving Appears at CIBF2023 Ceramic Rotary Kiln Helps Industry Upgrade